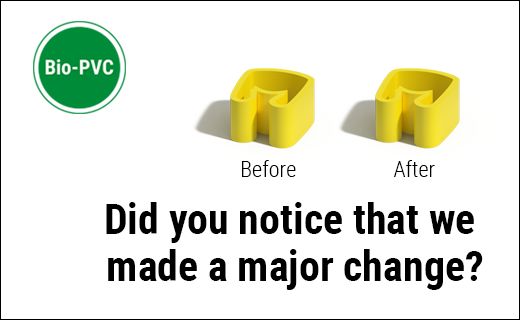

Partex Bio PVC reduces environmental impact

PURPOSEFUL AND STRATEGIC SUSTAINABILITY EFFORTS

At CSL we have been working hard to find ways to improve our sustainability and reduce our carbon footprint. By using compostable packaging and paper tape in our warehouse, allowing flexible work for our employees, and reducing unnecessary waste we have substantially reduced our environmental impact. It’s fantastic to see that our suppliers are working toward the same goal. In recent years, Partex has been working diligently and strategically to set goals for its sustainability efforts. This work is ongoing.

“We started by assessing the current situation deciding where to focus our efforts and setting goals to have the greatest impact. Finding an alternative material was identified as to be a priority to future-proof our products and reduce carbon footprint,” explains Peter Johansson, CEO of Partex’s production company in Gullspång.

“We will never be able to choose materials that degrade or have diminished properties over time. Our markings have to be fit for purpose. That’s why PVC plastic is hard to beat,” Peter continues.

In 2022, Partex conducted a project in collaboration with, among others, Chalmers Industriteknik to identify more sustainable materials for the production of their marking systems. An important requirement for any potential new material was that it had to be both more environmentally friendly and be at least as good as the material it would replace.

SAME PROPERTIES WITH IMPROVED SUSTAINABILITY

The project has been successful, and Partex is now commencing the launch of its products based on more sustainable materials. Johan Bengtsson, Director of Materials at Chalmers Industriteknik, comments:

“We are delighted to see that Partex is now introducing products made from more sustainable raw materials as a result of the successful joint project Partex conducted in collaboration with Chalmers University of Technology, RISE, and us at Chalmers Industriteknik. It shows that Partex is serious about its sustainability efforts and is not waiting to introduce these products to the market in response to regulatory or commercial reasons.”

“Our Bio-PVC is made from renewable raw materials, for example from pine oil from the forestry industry, explains Peter Johansson. The renewable raw materials have very similar properties as their fossil predecessors. It is so similar that we have been able to maintain our existing machinery, which again is a huge plus for the company’s sustainability efforts.

When the change is fully implemented, the CO2 impact from Partex’s products will have decreased by 80%.