The Ethernet interface enables events-driven transmission of diagnostic information. So, for example, measurement data about the pumps, which is continuously collected throughout their service life, provides information about their performance and operational status.

Diagnostic and status information that’s as comprehensive as possible and comes from all areas of an automation solution goes a long way in helping to optimise process control.

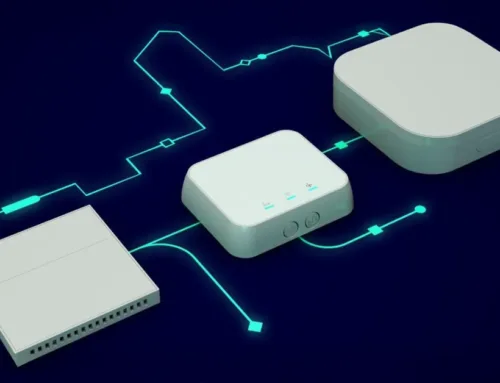

With the ACT20C gateway and the communication-capable signal converters, for the first time ever we can obtain process data from the signal conversion level – regardless of the automation solution selected. An Ethernet interface enables simple access to the desired information. The data obtained in the ACT20C gateway is provided via Modbus TCP or OPC, or can be displayed directly in an FDT frame application.

The flexibility of the ACT20C gateway makes it easy for you to optimise your processes. Depending on the communication infrastructure, you can make this data available throughout your entire network or pass it on to your SCADA or maintenance system. The data can even be used from any location over the Internet via an Industrial Ethernet router.

Your special advantages:

More transparency in your process automation

For the first time ever, extensive diagnostic and status information (which you can call up via the Ethernet interface) is available to you at status conversion level.

Product advantages

All the process parameters at a glance:

All the process parameters at a glance:

The status of devices, environmental conditions and functions is continually monitored over the Ethernet.

Simple commissioning, fast maintenance:

The station concept with “Plug & Produce” and “Hot Swapping” makes installation and maintenance work faster and thus more efficient.

Extensive diagnostics concept:

Support of fast and exact cause analysis according to NE107, NE43 and NE44.

Clever software configuration:

The software configuration based on the FDT and FDT2 standards makes parameterisation, documentation and data backup easier.

Technical information:

Technical information:

Contact CSL:

For more information please contact our Customer Support Team

Phone: 0800 288 423

Or email: team@cuthbertstewart.co.nz